-

SS Steel Pipes

-

Wear Resistance Steel Plate

-

Seamless Copper Pipe

-

Galvanized Aluminum Sheet

-

Carbon Steel Sheet Plate

-

Galvanized Steel Coils

-

Aluminum Alloy Tubes

-

Aluminum Steel Coil

-

Seamless Steel Pipes

-

Stainless Steel Coils

-

Stainless Steel Plate Sheet

-

Galvanized Steel Plates

-

Hollow Square Steel Tube

-

Hot Dipped Galvanized Steel Pipe

-

Welded Steel Pipes

-

YamThank you very much for your sincere service. The quality of your products has always been very good. We are very relieved and hope to have more cooperation in the future.

YamThank you very much for your sincere service. The quality of your products has always been very good. We are very relieved and hope to have more cooperation in the future. -

KhueThank you for your products. Your products are of good quality and considerate service. We are very confident and willing to cooperate with you. We hope there will be opportunities for cooperation with other products in the future.

KhueThank you for your products. Your products are of good quality and considerate service. We are very confident and willing to cooperate with you. We hope there will be opportunities for cooperation with other products in the future.

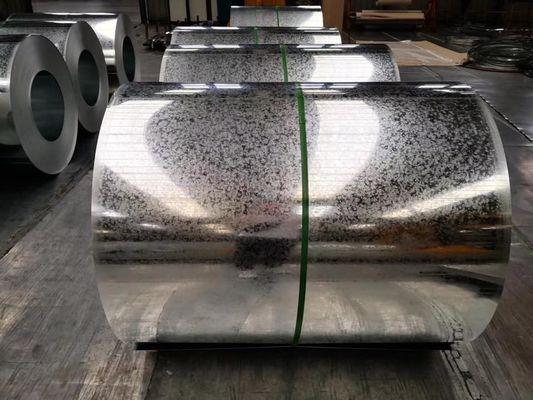

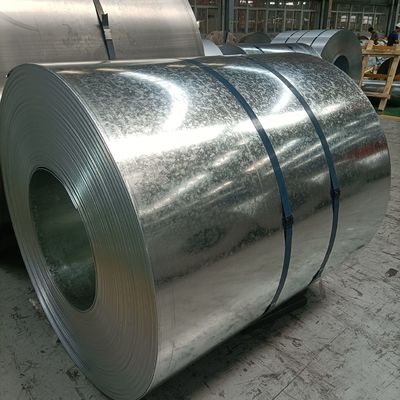

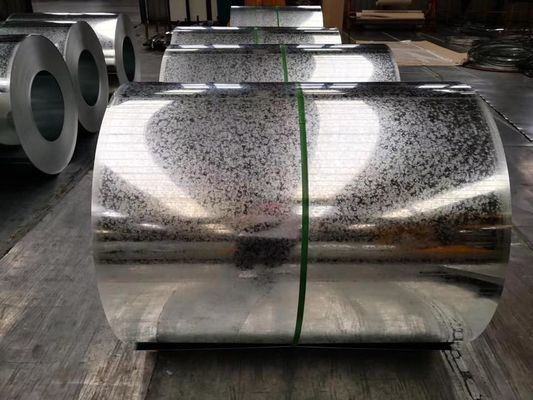

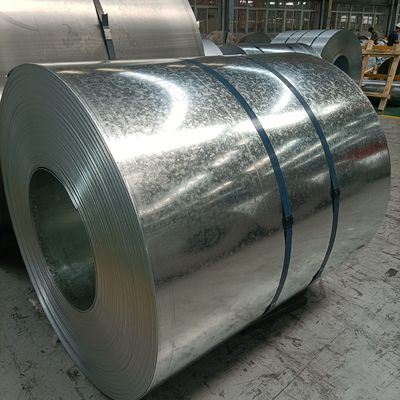

G550 Dx51d Gi Galvanized Steel Coils Metal G90 Z180 Regular Spangle Zinc Coated

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Edge | Slit Edge | Thickness | 0.12-0.2, 0.12mm-3.0mm |

|---|---|---|---|

| Spangle Type | Regular Spangle/Minimum Spangle | Grade | DX51D,SGCC,DX52D,ASTMA653,JISG3302 |

| Color | Silver | Technique | Hot Dipped |

| Highlight | Spangle Gi Galvanized Steel Coils,G550 Dx51d galvanized steel coil,G90 Z180 galvanized steel coil |

||

Regular Spangle/Minimum Spangle 600-1250mm Width Hot Dipped Dx51d Z275 Zinc Coated Galvanized Steel Coil

| Technical Standard | EN10147/EN10142/DIN 17162/JIS G3302/ASTM A653 |

| Grade | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD , S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490, SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80 (550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); or Customer's Requirement |

| Type | Coil/Sheet/Plate/Strip |

| Thickness | 0.125-6.00mm,or customer's requirement |

| Width | 600mm-1500mm,according to customer's requirement |

| Type of Coating | Hot Dipped Galvanized Steel(HDGI)/Electro-Galvanised Steel(EGI) |

| Zinc Coating | 20-275g/m2 |

| Surface Treatment | Passivation(C),Oiling(O),Lacquer sealing(L),Phosphating(P),Untreated(U) |

| Surface Structure | Normal spangle coating(NS),minimized spangle coating(MS),spangle-free(FS) |

| ID | 508mm/610mm,according to customer's requirement |

1. The mechanism of producing zinc flowers in the coating of hot-dip galvanized coil/sheet. Beautiful zinc flowers are a main feature of hot-dip galvanized coil

The most complete form of zinc crystal is similar to snowflake or hexagonal star, so the zinc crystal on the surface of strip steel is most likely to be shaped

Into snowflakes or hexagonal star zinc flowers.

1.1 conditions required for the formation of zinc flowers. Add two kinds of alloy elements with different properties to the zinc solution

Elements, one kind of which is fully soluble in molten zinc, but hardly soluble in solid zinc, such as lead and titanium;

The other is soluble in both liquid and solid zinc, such as aluminum, tin, antimony, etc. If you add a single

Although the alloy elements can change the surface state of the solidified coating, they cannot form typical zinc flowers,

Usually, the lead-free process we use to produce small zinc flowers is based on this principle.

1.2 the shape of zinc flower the shape of zinc flower depends on the type of two kinds of alloys, such as: selecting lead antimony can obtain

Get Phoenix Tail zinc flower; Choose lead tin to get sheep tooth zinc flower and so on. Crystal orientation of zinc flower on coating surface

Its appearance is different, and there are also differences in processing, such as: the processability of feathery zinc flowers in simple stretching and deep drawing

The processability of fern shaped and leaf shaped zinc flowers is the worst; While in bending and tension processing, leaves

The processability of zinc flower is the best, followed by feather zinc flower and sheep tooth zinc flower

Definition of galvanized coil coating

1, normal zinc flower coating During the normal solidification process, the zinc grains grow freely and the coating with obvious zinc flower morphology is formed.

2, small zinc flower coating During the solidification process of zinc layer, the zinc grains are artificially limited to form as fine zinc flower coating as possible.

3, no zinc flower coating By adjusting the chemical composition of the bath, the coating does not have visible zinc flower morphology, uniform surface.

4, zinc iron alloy coating After heat treatment of the steel strip through the galvanized tank, the entire coating into zinc and iron alloy layer, this coating appearance is dark gray, no metallic luster, easy to powder in the violent forming process, suitable for in addition to general cleaning, without further treatment can be directly painted coating.

5, the thickness of the coating,On both sides of galvanized steel plate, it is required to have different layers of coating weight.

6, finishing Finishing is a cold rolling of galvanized steel sheet with a small amount of deformation for one or more of the following purposes. Improve the surface appearance of galvanized steel plate or suitable for decorative coating; So that the finished product is not processed when the phenomenon of slip line or fold grain temporarily reduced to the minimum.

![]()

![]()