-

SS Steel Pipes

-

Wear Resistance Steel Plate

-

Seamless Copper Pipe

-

Galvanized Aluminum Sheet

-

Carbon Steel Sheet Plate

-

Galvanized Steel Coils

-

Aluminum Alloy Tubes

-

Aluminum Steel Coil

-

Seamless Steel Pipes

-

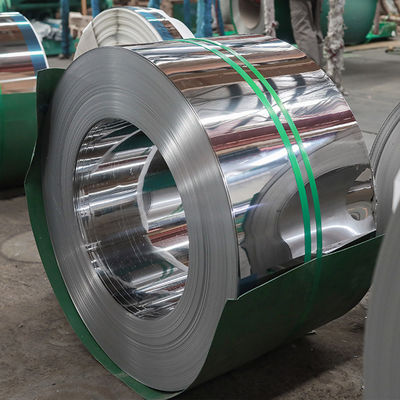

Stainless Steel Coils

-

Stainless Steel Plate Sheet

-

Galvanized Steel Plates

-

Hollow Square Steel Tube

-

Hot Dipped Galvanized Steel Pipe

-

Welded Steel Pipes

-

YamThank you very much for your sincere service. The quality of your products has always been very good. We are very relieved and hope to have more cooperation in the future.

YamThank you very much for your sincere service. The quality of your products has always been very good. We are very relieved and hope to have more cooperation in the future. -

KhueThank you for your products. Your products are of good quality and considerate service. We are very confident and willing to cooperate with you. We hope there will be opportunities for cooperation with other products in the future.

KhueThank you for your products. Your products are of good quality and considerate service. We are very confident and willing to cooperate with you. We hope there will be opportunities for cooperation with other products in the future.

2b 8K Hot Rolled Stainless Steel Coils Ba Hl Surface Perforated 201 202 304

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Surface | 2b/Ba/No.4/Mill Edge/Slit Edge | Thickness | 0.3~180mm |

|---|---|---|---|

| Model NO. | 400 Series | Process | Cold / Hot Rolled |

| Shape | Sheet/ Coils/Strips | Stock | Stock |

| Highlight | Hot Rolled Stainless Steel Coils,2b 8K Stainless Steel Coils,Perforated 201 Stainless Steel Coils |

||

No. 1 2b 8K Ba Hl No. 4 Surface Perforated 201 202 304 304L 316 316L Hot Rolled/ Cold Rolled Stainless Steel Coils

Product description

Stainless steel heat process

Stainless steel hot rolling process on the slab (mainly for the continuous casting billet) as raw material, after heat made strip roughing and finishing mill group. After finishing the Z a hot steel strip mill out through laminar flow cooling to the set temperature, rewinded into coils by the winder, after cooling coil are oxide skin surface, appear black, commonly known as "black volume of stainless steel". After annealing pickling, remove oxide surface, is the "white stainless steel roll", most of the hot rolled stainless steel market circulation white for stainless steel products.

Stainless steel cold rolling process:

After stainless steel hot rolling, some stainless steel hot rolling products are directly used downstream, some hot rolling products need to continue to be processed into cold rolling after use. Stainless steel cold rolling, the use of hot rolling thickness in 3.0-5.5mm thickness of stainless steel hot rolling products, after cold rolling equipment rolling processing, the production of stainless steel cold rolling products. At present, the main production process of stainless steel cold rolling is two types: stainless steel single stand cold rolling, stainless steel multi-stand cold rolling. The specific production process is as follows:After the cold rolling of stainless steel, it needs to go through annealing and pickling unit. The annealing of cold rolled stainless steel is through the process of recrystallization to eliminate work hardening and achieve the purpose of softening; The purpose of pickling is to remove the oxide layer formed on the surface of the steel strip during the annealing process, and to passivate the surface of stainless steel to improve the corrosion resistance of the steel plate/coil.

![]()