-

SS Steel Pipes

-

Wear Resistance Steel Plate

-

Seamless Copper Pipe

-

Galvanized Aluminum Sheet

-

Carbon Steel Sheet Plate

-

Galvanized Steel Coils

-

Aluminum Alloy Tubes

-

Aluminum Steel Coil

-

Seamless Steel Pipes

-

Stainless Steel Coils

-

Stainless Steel Plate Sheet

-

Galvanized Steel Plates

-

Hollow Square Steel Tube

-

Hot Dipped Galvanized Steel Pipe

-

Welded Steel Pipes

-

YamThank you very much for your sincere service. The quality of your products has always been very good. We are very relieved and hope to have more cooperation in the future.

YamThank you very much for your sincere service. The quality of your products has always been very good. We are very relieved and hope to have more cooperation in the future. -

KhueThank you for your products. Your products are of good quality and considerate service. We are very confident and willing to cooperate with you. We hope there will be opportunities for cooperation with other products in the future.

KhueThank you for your products. Your products are of good quality and considerate service. We are very confident and willing to cooperate with you. We hope there will be opportunities for cooperation with other products in the future.

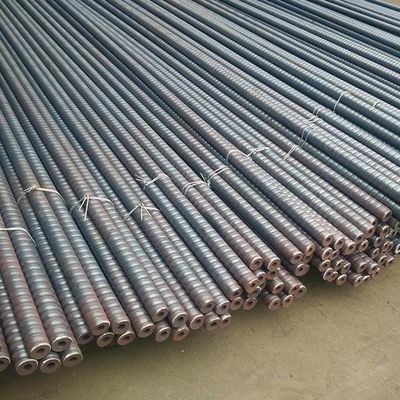

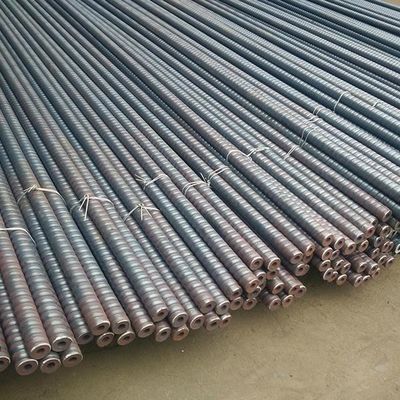

High Strength Seamless Steel Pipes 40mm Large Bearing Hollow Grouting Anchor Rod

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Carbon Steel, Alloy Steel | Model NO. | Hollow Bolts |

|---|---|---|---|

| Application | Surrounding Rock System Shoring And Supporting | Specification | OD:20-40mm |

| Tolerance | +0/-0.2mm | Test | Ultrasonic Test |

| Highlight | High Strength Seamless Steel Pipes,40mm Seamless Steel Pipes Rod,Hollow Grouting Anchor Rod |

||

High Strength and Large Bearing Capacity Skz Series Hollow Grouting Anchor Rod for Coal Mine

![]()

Product Description:

| Product Name | Hollow bolts / Rock bolts / Hollow grouting anchor rod / grouted hollow anchor bar | |

| Standards | GB1499.2-2007 GB 50086-2015 TB/T 3209-2008 | |

| Grades | Carbon | 45#, sae1045, aisi1045 |

| Alloy | 40Cr, JIS SCr440, ASTM 5140, ISO 41Cr4 | |

| Certificate | We are SGS approved enterprise, we issue MTC and be responsible for the quality. | |

| Outside diameter | 25mm, 25.4mm, 28mm, 28.3mm, 30mm, 32mm, or as per required | |

| Thread standard | ISO | |

| Tolerance for OD | +0mm/-0.2mm | |

| Length | 4-12m fixed length, or as per the required | |

| Surface treatment | Black / oiled, or as per required. | |

| Heat treatment | Annealed | |

| Test | Ultrasonic test | |

| Packing | Wrapped by steel strips, wrapped by steel strips | |

| Application | Surrounding rock system shoring and supporting | |

| Shipping term | In bulk / FCL / LCL, partial shipment allowed | |

| Shipping port | Qingdao, or Tianjin port | |

| Third party inspection | Acceptable | |

| Trade term | CIF, CFR, FOB, EXW | |

| Delivery time | Within 7 days for stocks supply. | |

| Paying term | 30%TT + 70% TT against copy of documents, or 30%TT + 70% LC. | |

Advantage&Function:

1. Immediately initial stage support for rock, control the surrounding rock being out of shape, guarantee the stability of surrounding rock.

2. Compared with solid rebar bolts, medium hollow design, makes the hollow bolts get the function of grouting pipe, it well avoids the waste and running off of mortar when grouting pipe pull out form the rock layer under traditional technology.

3. Mortar injecting well filled, what is more it can reaching goal of pressure mortar injection, finally the quality of project is improved.

4. Due to each accessories or parts effecting, the bolt neutral peculiarity is good. The mortar can fill every surface part of the hollow bolts, so the bolts get rid of being rusty, finally we get the goal of long term protection and supporting for rocks.

Installation Method:

- Using the jackdrill dig into the same depth of bolt length.

- Install the steel rising shell anchor head on the hollow bolt.

- Put hollow bolt into the ready hole.

- Install stopper mortar plug, base plate and nut on up side of hollow bolt.

- Reversal the bolt, and make anchor head' rising shell grasp well of hole.

- Fulfill the mortar.

Introduction of Hollow Grouting Anchor Cable:

Hollow grouting anchor cable is suitable for medium geological conditions, good surrounding rock permanent support, highway, railway, tunnel advanced support, slope support, foundation pit support and other projects.

Through the pressure grouting of hollow anchor body, the broken rock mass can be consolidated, the rock mass can be improved, and the good support purpose can be achieved.

By increasing the grouting pressure, the slurry can diffuse to the rock cracks around the borehole while filling the borehole and achieving full-length anchoring, which can bond and solidify the surrounding rock and realize deep hole anchoring.