-

SS Steel Pipes

-

Wear Resistance Steel Plate

-

Seamless Copper Pipe

-

Galvanized Aluminum Sheet

-

Carbon Steel Sheet Plate

-

Galvanized Steel Coils

-

Aluminum Alloy Tubes

-

Aluminum Steel Coil

-

Seamless Steel Pipes

-

Stainless Steel Coils

-

Stainless Steel Plate Sheet

-

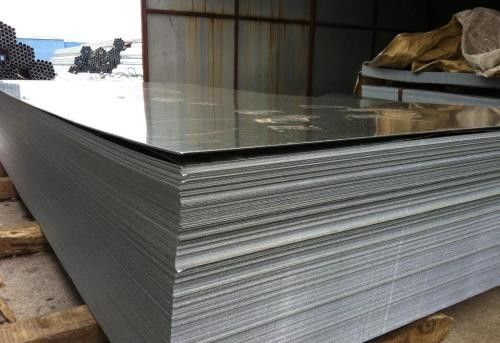

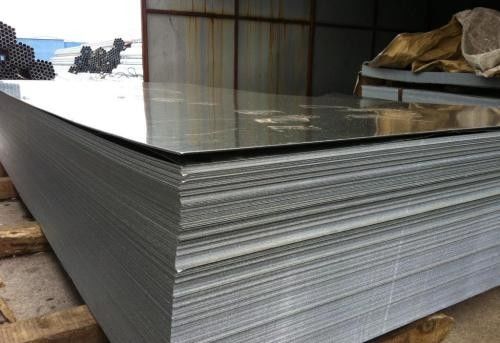

Galvanized Steel Plates

-

Hollow Square Steel Tube

-

Hot Dipped Galvanized Steel Pipe

-

Welded Steel Pipes

-

YamThank you very much for your sincere service. The quality of your products has always been very good. We are very relieved and hope to have more cooperation in the future.

YamThank you very much for your sincere service. The quality of your products has always been very good. We are very relieved and hope to have more cooperation in the future. -

KhueThank you for your products. Your products are of good quality and considerate service. We are very confident and willing to cooperate with you. We hope there will be opportunities for cooperation with other products in the future.

KhueThank you for your products. Your products are of good quality and considerate service. We are very confident and willing to cooperate with you. We hope there will be opportunities for cooperation with other products in the future.

0.18mm*1200mm Zinc Aluminium Roofing Sheet Color Coated Galvanized Steel Sheet

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Edge | Slit Edge | Application | Boiler Plate |

|---|---|---|---|

| Stock | Stock | Specification | 0.18mm*1200mm |

| Tensile/Bending Strength | 29.4MPa/ 45.6MPa | Thickness | 0.3-4mm |

| Highlight | 0.18mmx1200mm Aluminium Roofing Sheet,Color Coated Galvanized Steel Sheet,0.18mmx1200mm Steel Roofing Sheet |

||

0.18mm*1200mm Zinc Aluminium Roofing Sheet Color Coated Galvanized Plate Steel Sheet

|

Product name

|

Steel Roofing Sheet

|

|

Material

|

DX51D,DX52D,DX53D,DX54D,S250GD,S350GD,S550GD

|

|

Thickness

|

0.12-6mm

|

|

type

|

460/760/750/820/840/900/850/880/960/980/1050

|

|

Standard

|

ASTM/DIN/JIS/BS/GB/T

|

|

Zinc coating

|

40-275g/M2

|

|

Width

|

600-1500mm, usually 1250mm,1000mm,1240mm,1500mm,914mm,750mm and so on.

|

|

Grade

|

TDX51D+Z,TDX51D+AZ

|

|

Application

|

Villas, townhouse, apartments, tourist destination building, and roof conversion project

|

|

Paint Back (microns)

|

5-10 microns

|

|

Surface Treatment

|

1. Galvanized

2. PVC,Black and color painting 3. Transparent oil,anti-rust oil 4. According to clients requirement |

|

Coating

|

AZ30-AZ160, Z50-Z140g/m2

|

|

Surface

|

Matt, high gloss, double coated, wood pattern, marble pattern, winkle

|

By definition, hot rolling is rolling above the crystallization point, while cold rolling is rolling below the crystallization point.

Hot rolled plate rolling takes slab (mainly continuous casting slab) as raw material. The temperature control in the processing process includes rolling temperature and rolling temperature: rolling temperature is determined mainly according to the solid phase line temperature in the alloy phase diagram about 80%, and the final rolling temperature is determined according to the alloy plasticity diagram, requiring control in the alloy recrystallization temperature above (generally 8-900 degrees Celsius). After rolling, the sheet is cooled in air (in most cases), which is equivalent to normalizing. Due to the high temperature, the hot rolled plate will generate a layer of oxide iron on the surface, which naturally has a certain corrosion resistance. However, this layer of oxide iron sheet also makes the surface of hot rolled steel rough and the size fluctuation is large. Hot rolled plate coil is generally medium thickness plate, thickness > 4mm, due to the limitation of rolling accuracy, the thinnest rolling thickness of hot rolling process is 0.6mm.

Cold rolled coil rolling is made of hot rolled coil. After removing the oxide scale by pickling, the steel is extruded under the pressure of the roller at room temperature, and the hard roll is obtained by pressure machining. Due to the deterioration of the cold rolling process, the toughness and plasticity of the rolled hard coil should be restored to a certain extent by annealing treatment so as to obtain the cold rolled coil with mechanical properties up to the specified standard. Because of the pickling process, the surface of the cold rolled sheet is smooth and smooth. Cold rolled coil is generally thin plate, thickness < =4mm, cold rolling process at present the thinnest can roll steel foil thickness of 0.01mm.

To sum up, hot rolled steel is easy to roll, high efficiency. Cold rolling requires large mill power, low rolling efficiency, and in order to eliminate work hardening in the rolling process also need intermediate annealing, so the cost is high.

In terms of comprehensive mechanical properties and process properties, there is no essential difference between cold rolled coil and hot rolled coil after annealing, but it is superior to hot rolled coil in appearance, hardness and surface properties. The superior surface performance of cold-rolled coil represents that the performance of cold-rolled coil is stronger than that of hot-tied coil in the reprocessing process of plate such as color coating and coating. Therefore, cold-rolled coil is often used to manufacture passenger vehicles, refrigerators, washing machines and other household appliances, which have a certain demand for rust prevention and face consumers. Compared with cold rolling, hot tie coil has the advantage of short process and low cost. It is mainly used in the manufacture of steel structure parts, Bridges, ships and commercial vehicles (trucks, buses, agricultural machinery), etc., which has higher economic requirements and lower appearance requirements.

In general, the advantages and disadvantages of hot rolled coil and cold rolled coil depend on the downstream manufacturers' use and cost performance analysis, and no one is significantly better than the other party. However, it should be noted that cold rolled coil and hot rolled coil cannot be substituted for each other in most of the time, especially in the production of automotive performance parts and other parts that have higher requirements on the surface quality and mechanical properties of steel.

![]()