-

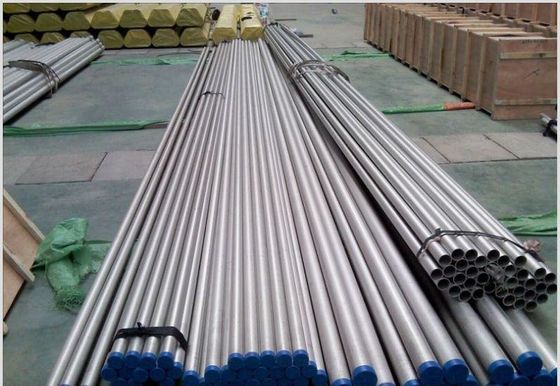

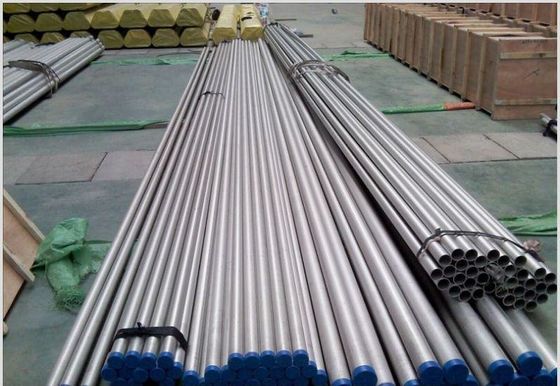

SS Steel Pipes

-

Wear Resistance Steel Plate

-

Seamless Copper Pipe

-

Galvanized Aluminum Sheet

-

Carbon Steel Sheet Plate

-

Galvanized Steel Coils

-

Aluminum Alloy Tubes

-

Aluminum Steel Coil

-

Seamless Steel Pipes

-

Stainless Steel Coils

-

Stainless Steel Plate Sheet

-

Galvanized Steel Plates

-

Hollow Square Steel Tube

-

Hot Dipped Galvanized Steel Pipe

-

Welded Steel Pipes

-

YamThank you very much for your sincere service. The quality of your products has always been very good. We are very relieved and hope to have more cooperation in the future.

YamThank you very much for your sincere service. The quality of your products has always been very good. We are very relieved and hope to have more cooperation in the future. -

KhueThank you for your products. Your products are of good quality and considerate service. We are very confident and willing to cooperate with you. We hope there will be opportunities for cooperation with other products in the future.

KhueThank you for your products. Your products are of good quality and considerate service. We are very confident and willing to cooperate with you. We hope there will be opportunities for cooperation with other products in the future.

4inch Polished Ss Pipe 2205 Duplex Stainless Steel Pipe

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Width | 1000-3500mm | Length | 2000-6000mm |

|---|---|---|---|

| Grade | 201, 304, 316, 430 | Technique | Cold Rolled |

| Application | Mold & Dies, Ship Plate | Surface Finish | 2B |

4inch Polished Ss Pipe 2205 Duplex Stainless Steel Pipe

| Product Name | Stainless steel pipe |

| Type | Cold Drawn or Hot Rolled |

| Thickness | 0.1-300mm |

| Width | 1000, 1219, 1500, 2000, 2500, 3000mm etc. |

| Length | 1000, 1500, 2438, 3000, 5800, 6000, 9000, 12000mm etc. |

| Standard | ASTM JIS AISI GB DIN EN |

| Surface Finished | BA, 2B, NO.1, NO.4, 4K, HL, 8K |

| Application | It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components. It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc. . |

| Certification | CE, ISO, SGS, BV |

| Technique | Hot rolled or cold drawing |

| Edge | Mill Edge / Slit Edge |

| Quality | SGS Inspection |

| Grade(ASTM UNS) | 201 202 301 304 304L 321 316 316L 317L 347H 309S 310S 904L S32205 2507 254SMOS 32760 253MA N08926 etc. |

| Grade (EN) | 1.4301, 1.4307, 1.4541, 1.4401, 1.4404 ,1.4571, 1.4438, 1.4539, 1.4547, 1.4529, 1.4562, 1.4410, 1.4878, 1.4845, 1.4828, 1.4876, 2.4858, 2.4819 |

| Main market | Asia/Europe/ South America |

| Delivery time | Within 7-10 Working Days |

| Port of Loading | Qingdao, China |

| Price Terms | CIF CFR FOB EX-WORK |

| Export Packing | Waterproof Paper, Steel Strip Packed and other Standard Export Seaworthy Package, or customized package |

| Supply Ability | 5000 Ton/Tons per Month |

| Payment Terms | T/T L/C and Western Union etc. |

Duplex stainless steel tube has good welding performance, compared with ferritic stainless steel and austenitic stainless steel, it is not like the welding heat affected zone of ferritic stainless steel, because of the severe coarsing grain and the plastic toughness is greatly reduced, nor like austenitic stainless steel, is more sensitive to welding hot crack.

Because of its special advantages, duplex stainless steel is widely used in petrochemical equipment, seawater and wastewater treatment equipment, oil and gas pipelines, papermaking machinery and other industrial fields. In recent years, it has also been studied in the field of bridge bearing structure, with good prospects for development.

Duplex stainless steel is in its solid quenching structure of ferritic phase and austenite phase accounted for half, generally the minimum phase content may be up to 30%.

Compared with austenitic stainless steel, the advantages of duplex stainless steel

(1) the yield strength is more than twice as high as ordinary austenitic stainless steel, and it has enough plastic toughness required for molding. The wall thickness of tanks or pressure vessels made of duplex stainless steel is 30-50% less than that of commonly used austenite, which is beneficial to reduce costs.

(2) with excellent stress corrosion cracking ability, even the lowest alloy content of duplex stainless steel has higher stress corrosion cracking ability than austenitic stainless steel, especially in the environment containing chloride ions. Stress corrosion is a difficult problem for ordinary austenitic stainless steel.

(3) in many media the most commonly used 2205 duplex stainless steel corrosion resistance is better than ordinary 316L austenitic stainless steel, and super duplex stainless steel has high corrosion resistance, and some media, such as acetic acid, formic acid and so on can even replace high alloy austenitic stainless steel, and corrosion resistant alloy.

(4) has good local corrosion resistance, compared with the alloy content of austenitic stainless steel, its wear corrosion and fatigue corrosion performance is better than austenitic stainless steel.

(5) the linear expansion coefficient is lower than austenitic stainless steel, and close to carbon steel, suitable for connection with carbon steel, has important engineering significance, such as the production of composite plate or lining.

(6) regardless of dynamic or static load conditions, than austenitic stainless steel has higher energy absorption capacity, which for the structural parts to cope with emergencies such as collision, explosion, etc., duplex stainless steel has obvious advantages, has practical application value.

![]()