-

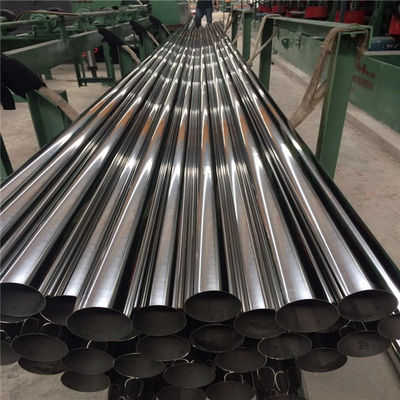

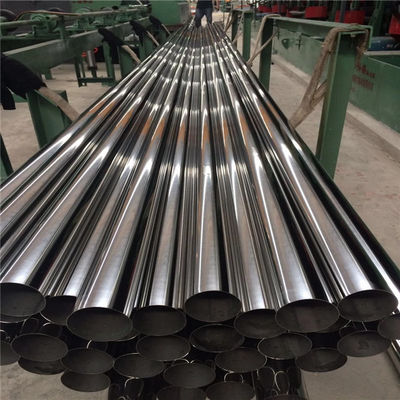

SS Steel Pipes

-

Wear Resistance Steel Plate

-

Seamless Copper Pipe

-

Galvanized Aluminum Sheet

-

Carbon Steel Sheet Plate

-

Galvanized Steel Coils

-

Aluminum Alloy Tubes

-

Aluminum Steel Coil

-

Seamless Steel Pipes

-

Stainless Steel Coils

-

Stainless Steel Plate Sheet

-

Galvanized Steel Plates

-

Hollow Square Steel Tube

-

Hot Dipped Galvanized Steel Pipe

-

Welded Steel Pipes

-

YamThank you very much for your sincere service. The quality of your products has always been very good. We are very relieved and hope to have more cooperation in the future.

YamThank you very much for your sincere service. The quality of your products has always been very good. We are very relieved and hope to have more cooperation in the future. -

KhueThank you for your products. Your products are of good quality and considerate service. We are very confident and willing to cooperate with you. We hope there will be opportunities for cooperation with other products in the future.

KhueThank you for your products. Your products are of good quality and considerate service. We are very confident and willing to cooperate with you. We hope there will be opportunities for cooperation with other products in the future.

Hot Rolled Precision Seamless Stainless Steel Pipe Tube 19*1mm Stainless Steel Pipe

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| After-sales Service | One Year | Warranty | One Year |

|---|---|---|---|

| Technique | Hot Rolled | Surface Treatment | Polish Or Pickling |

| HS Code | 7304112000 | Standard | ASTM A321 |

Hot Rolled Precision Seamless Stainless Steel Pipe Tube 19*1mm Stainless Steel Pipe

Stainless steel tube is a hollow strip of circular stainless steel. The commonly used material of stainless steel round tube is SUS201,202,304,316 and so on. Stainless steel round pipe is widely used in home decoration (balustrade, anti-theft net, stair handrail, balcony guardrail, curtain rod, etc.), chemical, chemical fertilizer, chemical fiber, natural gas, oil, aviation, food, water conservancy, electric power, medicine, boiler heat exchange, etc.

Stainless steel pitting

Causes:

Pitting corrosion of stainless steel occurs in the environment containing iodine, chlorine, bromine and other aqueous solutions. The reason for the pitting corrosion of stainless steel is that chlorine ions are active anions, which are easily adsorbed, crowded out oxygen atoms, and cations in the passivation film react to generate soluble chloride, destroy the passivation film, form small holes, and become pitting inducement stage, forming a block circuit at this stage, the phenomenon of current corrosion.

Preventive measures:

1, in the known pitting environment to choose the appropriate stainless steel material, the experiment shows that the higher the content of Mo or Mn stainless steel, the stronger the pitting resistance;

2. Control the ph, chloride concentration and temperature of liquid in contact with stainless steel;

3, cathodic protection, anode protection or both of the two protection measures;

4, as far as possible to use better quality stainless steel, such as 316 or 316L, to improve the pitting resistance of stainless steel rod.

304 stainless steel tube introduction:

In the air or chemical corrosion medium can resist corrosion of a high alloy steel, 304 stainless steel tube is a beautiful surface and good corrosion resistance, do not have to be plated and other surface treatment, and play the inherent surface properties of stainless steel, used in many aspects of a kind of steel.

304 stainless steel tubes are usually called stainless steel. On behalf of the performance of 13 chromium steel, 18-8 chromium nickel steel and other high alloy steel. From the metallographic point of view, because stainless steel contains chromium and the surface of the formation of a very thin chromium film, the film separated from the oxygen in the steel invasion of corrosion resistance. To maintain the corrosion resistance inherent in stainless steel, steel must contain more than 12% chromium. 304 is a universal stainless steel, which is widely used in the manufacture of equipment and parts requiring good comprehensive properties (corrosion resistance and formability). 304 stainless steel is a brand of stainless steel produced in accordance with ASTM standards in the United States. 304 is equivalent to China's 0Cr19Ni9 (0Cr18Ni9) stainless steel.

304 stainless steel properties:

304 stainless steel is widely used as a chromium - nickel stainless steel, with good corrosion resistance, heat resistance, low temperature strength and mechanical properties. Corrosion resistance in the atmosphere, if it is an industrial atmosphere or heavily polluted area, it needs to be cleaned in time to avoid corrosion. Suitable for food processing, storage and transportation. It has good machinability and weldability.

Use of 304 stainless steel tube:

(1) Civil pipe is divided into round pipe, rectangular pipe, flower pipe, generally used for decoration, construction, structure and other aspects;

(2) Industrial pipe: industrial piping steel pipe, general piping steel pipe (drinking water pipe), mechanical structure/fluid conveying pipe,

Furnace heat exchange pipe, food sanitation pipe, etc. Generally used in various fields of industry such as: petrochemical, papermaking, nuclear energy, food, beverage, and other industries require higher fluid medium pipeline.

| Commodity Name | Stainless steel pipe |

| Type | Seamless |

| Standard | ASTM A554, A249,A269,A270 , A312 |

| Material | 201,202,301,304,304L,316,316L,316Ti,321,410,430 |

| Outer Diameter | 0.1 - 500 mm |

| Wall Thickness | 0.25-40mm |

| Length | customize |

| Tolerance | OD±1% WT±5% or as per customers' request |

| Surface | Satin/Hairline/Mat/Pickling 400G,500G,600G or 800G Mirror finish |

| Test | Squash test, extended test, water pressure test, crystal rot test, heat treatment, NDT |

| Application | Construction, Industry, Petroleum, Chemical, Boiler and Exchanger |

![]()