-

SS Steel Pipes

-

Wear Resistance Steel Plate

-

Seamless Copper Pipe

-

Galvanized Aluminum Sheet

-

Carbon Steel Sheet Plate

-

Galvanized Steel Coils

-

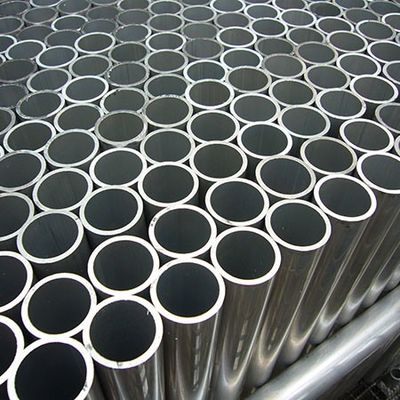

Aluminum Alloy Tubes

-

Aluminum Steel Coil

-

Seamless Steel Pipes

-

Stainless Steel Coils

-

Stainless Steel Plate Sheet

-

Galvanized Steel Plates

-

Hollow Square Steel Tube

-

Hot Dipped Galvanized Steel Pipe

-

Welded Steel Pipes

-

YamThank you very much for your sincere service. The quality of your products has always been very good. We are very relieved and hope to have more cooperation in the future.

YamThank you very much for your sincere service. The quality of your products has always been very good. We are very relieved and hope to have more cooperation in the future. -

KhueThank you for your products. Your products are of good quality and considerate service. We are very confident and willing to cooperate with you. We hope there will be opportunities for cooperation with other products in the future.

KhueThank you for your products. Your products are of good quality and considerate service. We are very confident and willing to cooperate with you. We hope there will be opportunities for cooperation with other products in the future.

1.9mm Aluminum Alloy Tubes Customized Precision Decorative 6061t6 6063

| Place of Origin | China |

|---|---|

| Brand Name | Aluminum Alloy Tubes |

| Certification | ISO9001 |

| Model Number | Tongmao |

| Minimum Order Quantity | 3 Tons |

| Price | $500 per ton |

| Packaging Details | Sea Worth Packaging or Client's Request |

| Delivery Time | 5 - 15 Working Days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram |

| Supply Ability | 500 Tons - 1 Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Aluminum Alloy Tube | Standard | ASTM, AISI, EN, JIS, GB, API, DIN |

|---|---|---|---|

| Grade | AA10, AA15, AA20, AA25 | Alloy Or Non Alloy | Alloy |

| Technique | Hot Rolled Cold Rolled, Anodized | Thickness | 0.3 Mm - 1.9mm |

| Highlight | 1.9mm aluminum alloy tubes,6061t6 aluminum alloy tubes,t6 6063 aluminum tube |

||

(1).Aluminum anodized tube for fishing poles tent poles ski poles

(2).20 years warranty.

(3).High corrosion resistance.

(4).5-10 years weather resistance.

(5).Good wear resistance & anti-scratch.

(6).Size customized.

(7).Alloy temper:7001-T5;7075-T6,etc.

(8).Standard: EN755, ASTMB221, DIN Standard

(9).Surface treatment: Mill finishes;Anodized; Powder coated;Wooden grain, Machine/Acid polished and etc.

(10).Applicant:Car; Aerospace; Ship; Armarium; Industrial equipment; and etc.

(11).Packing details:Shrinking film, Carton,Wooden pallet or By customer's requirements.

(12)..Delivery: 25-30 days for mass production

| Surface Finish: | Mill finish | Anodizing | Powder Coating | Wood Grain | Electrophoresis | Polished | Brushed |

| Color: | Anodizing: | Silver, bronze, champagne, titanium, nickel, golden yellow, etc. | |||||

| Anodizing thickness is up to 25um. | |||||||

| Powder Coating: | White, black, bronze, grey, green, etc . | ||||||

| Powder coating thickness is more than 60um. | |||||||

| Wood Grain: | 1. Italian MENPHIS transfer printing paper. | ||||||

| 2. AKZO NOBEL INTERPON D1010(10 years warranty): Australia ceder, Bush cherry, Chest nut, Jarrah I, Jarrah II, Western red ceder, etc. | |||||||

| 3. AKZO NOBEL INTERPON D34(5 years warranty): Bush wood, Western red, Jarrah, Snow gum, etc. | |||||||

| Electrophoresis: | Silver, nickel, golden yellow, black, champagne, etc | ||||||

| Polishing | Silver, nickel, golden yellow, black, etc | ||||||

| Brushing: | Silver, nickel, golden yellow, black, bronze, etc | ||||||

| Machining: | Cutting, punching, drilling, bending, weld, mill, CNC, etc. | ||||||

ADODIZINMG QUALITY |

||||

Grade |

corrosion resistance |

abrasive resistance |

||

CASS test |

alkaline dropping test |

sandtrial Abrasion coefficient f,g/um |

||

hours |

grade |

|||

AA10 |

16 |

≥ 9 |

≥ 50 |

≥ 300 |

AA15 |

32 |

≥ 9 |

≥ 75 |

≥ 300 |

AA20 |

56 |

≥ 9 |

≥ 100 |

≥ 300 |

AA25 |

72 |

≥ 9 |

≥ 125 |

≥ 300 |

Q1: What is your MOQ?

A: 500kg for general products. More than 5 tons for new products.

Q2: Can you produce aluminum profiles by drawing?

We have professional engineer to design CAD drawing and establish mould according to customers' requirement.

Q3: What certification do you have? What's your standard?

A: We have ISO certification. Our standard is DIN, AAMA, AS/NZS, China GB.

Q4: What's the delivery time for samples and mass production?

A: (1). 2-3 weeks to open the new moulds and make free samples.

(2). 3-4 weeks after receipt of deposit and confirmation of the order.

Q5: What's the packing way?

A: Commonly we use shrink films or kraft paper, also we can make as per customers' requirements.

Q6: What's the payment terms?

A: Usually by T/T, 30% deposit and the balance paid before shipment, L/C is acceptable.