-

SS Steel Pipes

-

Wear Resistance Steel Plate

-

Seamless Copper Pipe

-

Galvanized Aluminum Sheet

-

Carbon Steel Sheet Plate

-

Galvanized Steel Coils

-

Aluminum Alloy Tubes

-

Aluminum Steel Coil

-

Seamless Steel Pipes

-

Stainless Steel Coils

-

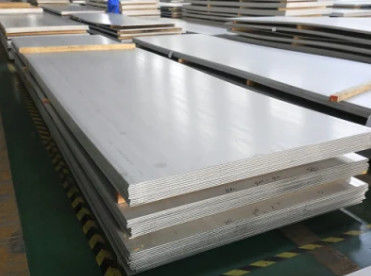

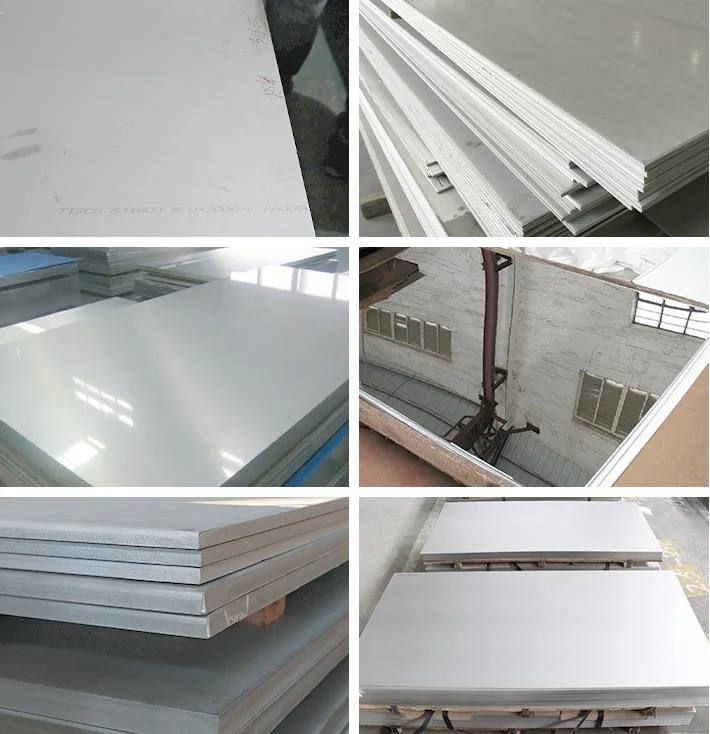

Stainless Steel Plate Sheet

-

Galvanized Steel Plates

-

Hollow Square Steel Tube

-

Hot Dipped Galvanized Steel Pipe

-

Welded Steel Pipes

-

YamThank you very much for your sincere service. The quality of your products has always been very good. We are very relieved and hope to have more cooperation in the future.

YamThank you very much for your sincere service. The quality of your products has always been very good. We are very relieved and hope to have more cooperation in the future. -

KhueThank you for your products. Your products are of good quality and considerate service. We are very confident and willing to cooperate with you. We hope there will be opportunities for cooperation with other products in the future.

KhueThank you for your products. Your products are of good quality and considerate service. We are very confident and willing to cooperate with you. We hope there will be opportunities for cooperation with other products in the future.

Stainless Steel Coil Sheet Plate/201 301 304 304L 316 316L 309S 310S 321 347 2205 410 420 Stainless Steel Plate

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Model NO. | DC53 HRC60 ~ 62 | Hardness | 40hrb--95hrb |

|---|---|---|---|

| Sample | Provide | Base Material | Cold/Hot Coil Steel |

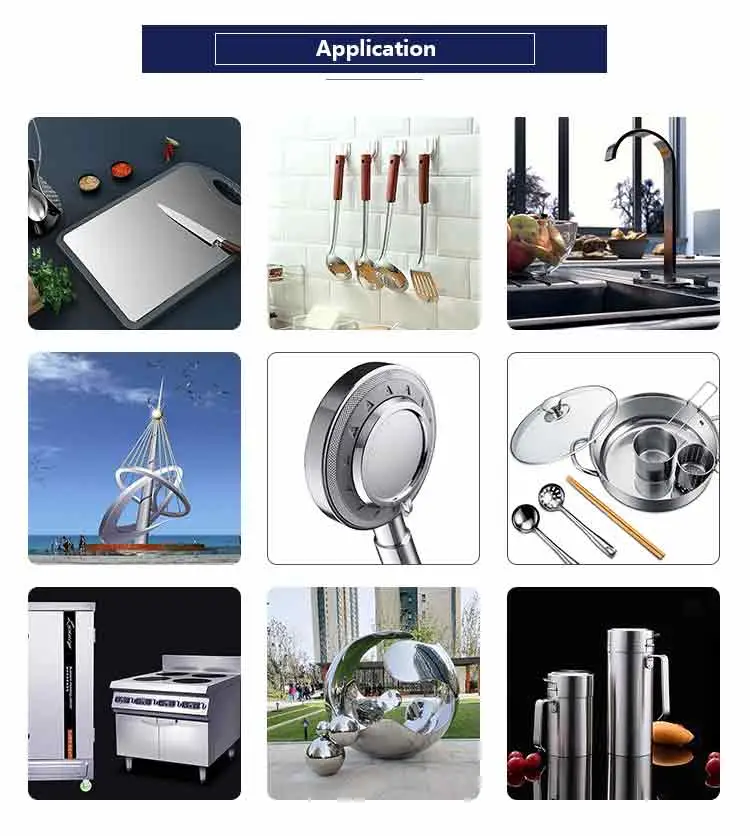

| Zinc Coating | 40-600G/M2 | Application | Mold & Dies, Ship Plate, Boiler Plate, Container Plate, Flange Plate |

Stainless Steel Coil Sheet Plate/201 301 304 304L 316 316L 309S 310S 321 347 2205 410 420 Stainless Steel Plate

| Product Name | Stainless Steel Coil Sheet Plate/201 301 304 304L 316 316L 309S 310S 321 347 2205 410 420 Stainless Steel Plate |

| Material | High chromium carbide overlay wear resistant steel |

Thickness |

4+4 5+3 6+4 6+5 8+4 8+6 8+8 10+4 10+6 10+8 10+10 12+4 12+6 12+8 12+10 14+6 14+8 14+10 16+6 16+8 16+10 16+12, etc. or as customized |

| Weldable Thickness | 3-20mm |

Hardness |

HRC 52-62 Wear deposite 3mm: HRC 52-58, 4mm: HRC 56-60, 5mm: HRC 58-62, 6mm: HRC 58-62, 8mm: HRC 58-62, 10mm: HRC 60-62, 12mm: >62 |

| HRC of 1st layer :52-58; HRC of 2nd layer: 58-62; HRC of Pure weld deposite: 62 | |

| Surface Treatment | Hardfacing clading coated. |

| Technique | Advanced automatic self-shilded open arc welding |

Chemical Composition |

Take 6+6 wear resistant steel for example: C : 4.3-4.8% Cr : 23-30% Mn : 0.8-1.1% Mo: 0.08-0.18 Ni:0.08-0.15 Other Metal elements : Micro |

| Base Plate | Q235B, All weldable steels, mostly structural steels. |

Feature |

High wear resistance 12-20 times higher than common plate 5-10 times than low alloy steel plate 2-3 times than high chromium cast iron plate |

1. Steel Grade:

China:NM400,NM360,NM500,NM600,Mn13

Japan:-EH400,-EH450,-EH500

Finland: RAEX400,RAEX450,RAEX500

Germany:DILLIDUR400V/450V/500V,XAR400/450/500

2. Size:

Thickness: 6-150mm

Width:1500-2500mm;

Length:customized

3. Technique:Hot Rolled, Cutting

4. Origin: China, Japan, Finland, Germany

5. Packing:Standard export package

6. Delivery:Large stock for normal sizes, Special size will be deliverd within 30 working days.

7. Test:SGS, BV is available

8. Payment: 30%T/T in advance, balance payment against full set shipment documents by T/T or L/C

| Chemical composition and mechanical properties of stainless steel coils | |||||||||

| Grade | Chemical Composition (%) | Mechanieal Performece | |||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Hardness | |

| 201 | ≤0.15 | ≤1.00 | 5.5/7.5 | ≤0.060 | ≤0.030 | 3.5/5.5 | 16.0/18.0 | - | HB≤241,HRB≤100, HV≤240 |

| 304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.0/11.0 | 18.00/20.00 | - | HB≤187,HRB≤90,HV≤200 |

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.00/14.00 | 16.0/18.0 | 2.00/3.00 | HB≤187, HRB≤90 HV≤200 |

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.00/14.00 | 16.0/18.0 | 2.00/3.00 | HB≤187, HRB≤90 HV≤200 |

| 410 | ≤0.15 | ≤1.00 | ≤1.25 | ≤0.060 | ≤0.030 | ≤0.060 | 11.5/13.5 | - | HB≤183, HRB≤88 HV≤200 |

| 430 | ≤0.12 | ≤1.00 | ≤1.25 | ≤0.040 | ≤0.03 | - | 16.00/18.00 | - | HB≤183, HRB≤88 HV≤200 |

| Trade Terms | EXW, FOB, CIF, CRF, DAP |

MOQ |

1 Ton |

| Payment terms | 1).30% deposit, the balance before loading by T/T 2).30% deposit, the balance against copy of B/L by T/T 3).30% deposit by T/T, the balance by L/C at sight 4).100% L/C at sight |

Lead time |

5~10 days after get deposit or origin L/C document |

FAQ

1.Can we supply the sample ?

Yes,we can supply the sample.You can tell us the detail size.

2.Can we accept customize?

Yes,we can.We can manufacture as customer's requirement.You can send the CAD or drawing to us.

3.Quality problem?

According to the standard for production.And the products must pass the quality inspection department.We also accept Third Part Inspection.

4.Delivery time?

Prompt delivery for standard size,or under the contract.

5.Payment term?

Under the contract.

6.Other problem?

You can contact our customer service staff to ask help.